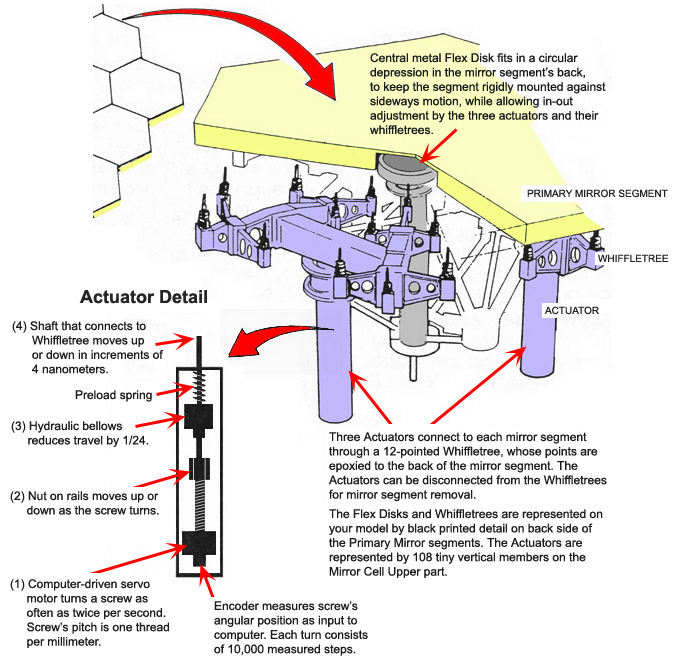

Keck Telescope SCIENCE KIT Fact SheetPart 3. Keck Telescope Segmented Primary MirrorEach of Keck's thirty-six hexagonal primary mirror segments have a nearly perfect shape. If the primary mirror were enlarged to the diameter of Earth, imperfections on the segments' reflective surfaces would be less than one meter high. To keep all thirty-six segments in perfect alignment with the whole primary mirror's hyperboloid shape, the computer-driven actuators articulate the individual 1.8-meter diameter mirror segments in steps of only four nanometers up or down: 1/250 of a micron. Such is the precision needed for the ten-meter segmented mirror to bring distant starlight to focus.

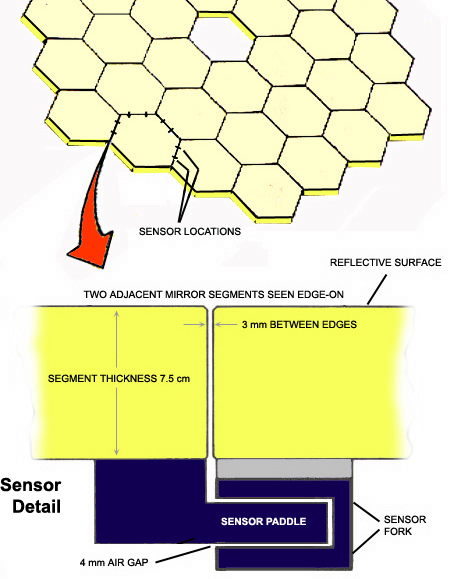

To permit computer software to control the primary mirror's shape in real time, inputs are provided by two electronic sensors positioned on every edge that adjoins another segment. There are 168 of these sensors. Each of the electronic sensors employs the ratio of the capacitances of two air-gap capacitors. These two capacitors comprise the sensor paddle's top and bottom surfaces, and the two inner surfaces of the sensor fork. As the vertical displacement between the mirror segments changes, this change is reported as a change in capacitance. This analog electronic signal is then converted to a digital signal and sent to the computer.

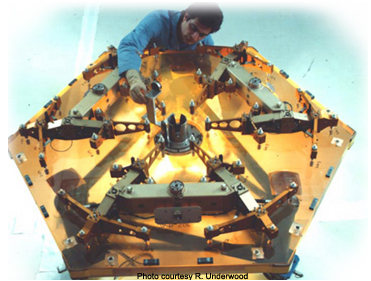

Compare this photo with markings on the back of the Primary Mirror in your kit.

| SCI HOME PAGE | CATALOG | HOW TO ORDER | GREAT SPACE LINKS |

|